Control automático y supervisión remota de un biorreactor Stirred Tank

Automatic Control and Remote Supervision of a Stirred

Tank Bioreactor

s

Fernando Hernández[1], Carlos Cigliutti[2], André Fonseca[3]

Recibido: Febrero 2020 Aceptado:

Noviembre 2019

Resumen.- El diseño

cuidadoso de un sistema de biorreactor regulado, eficiente, escalable y

portátil para el análisis de una variedad cada vez mayor de procesos biológicos

y químicos es actualmente de suma importancia para el desarrollo de la

Biotecnología. La interacción mutua existente de las variables involucradas

dificulta la optimización del sistema e insta a la necesidad de integrarlo con

un alto rendimiento y adaptabilidad contra los cambios en respuesta a

diferentes características. En el documento se propone un método validado para

la regulación de la velocidad de agitación y temperatura del biorreactor, así

como el pH del compuesto mediante técnicas tradicionales basadas en ON-OFF,

integradores, derivadores y controles Fuzzy. El sistema resultante permite su

configuración y supervisión ya sea local o remotamente con encriptación,

gestionando apropiadamente el contenido almacenado e intercambiado entre

dispositivos.

Palabras clave: Biorreactor; Bioproceso; Sistema de Control; Adaptabilidad;

Mantenibilidad

Summary.- The careful design of a regulated, efficient, scalable

and portable bioreactor system for the analysis of an ever-growing variety of

biological and chemical processes is currently of paramount importance for the

development of Biotechnology. The existing mutual interaction of the variables

involved hinders the optimization of the system and urges the need to embed it

with high performance and adaptability against changes in response to different

characteristics. In this paper is proposed a validated method for the

regulation of the bioreactor’s agitation speed and temperature as well as

compound pH by traditional techniques based on ON-OFF, integrators, derivatives

and Fuzzy controls. The resulting control system enables its configuration and

supervision either locally or remotely with encryption, managing the content

stored and exchanged between devices.

Keywords: Bioreactor; Bioprocess; Control System; Adaptability;

Maintainability

1. Introduction.- Bioreactors are the main units

of operation for the industrial biochemical transformation in which the treated

materials promote biological transformation by the action of living cells or by

cellular components such as enzymes [1]. They consist of standard systems in

either size and functionality composed of a complex set of pipes, fittings,

cables, sensors and actuators where the fermentation process and all its

consequent biological reactions are carried out, causing a major design

challenge for individuals of the area who need

to make a prior intensive analysis of the compound to be processed. This

is justified by the differential behavior of each reaction the system ought to

put through, estimating and considering the interactions with substances or

unavoidable elements of the environment that are often unwanted.

With the objective of

optimizing cell growth in order to obtain a reduction in fabrication and

commercialization times, new types of bioreactors technologies are constantly

being developed to continue improving productivity, pursuing the most efficient

expression of the biological properties of usual microorganisms to achieve more

favorable interactions between cells and culture media [2].

This is obligatory sought in a

tightly controlled environment, providing efficient means of mixing, mass

transfer and heat between the different bioprocesses phases with both complex

non-linear and dynamic properties and delicate environment conditions.

The control of a bioreactor takes into account several variables that

influence each other in distinctive degrees, such as the pH of the sample, the

temperature of the compound, the level of dissolved oxygen and the speed of the

agitation. Each variable affects the study compound differently and must therefore

be considered and treated differently. Thus, it is proposed an automatism

composed of multiple controllers that allow to regulate and modify the

aforementioned relevant variables of the system.

The desired automation is mainly focused on maintaining an acceptable

and stable performance though considering the organisms standard growth

conditions and rapid adaptation of the systems response against unscheduled

changes generated by the environment or the organic reaction itself.

|

|

|

Figure I.- CIM Model of the proposed system design |

As

shown in Figure I, the architecture of the proposed system is centralized in a

master controller located in a Raspberry Pi, on which to develop the main

controllers, user management and auxiliary functions, as well as the web server

for remote supervision. This master controller communicates with slave

controllers consisting of both traditional Arduinos and various devices of

tertiary companies. This chosen design is argued by its simplicity and

coherence, seeking general control focused on a single device that is

responsible for the processing and delegate of data and information. This

decision also facilitates the use, scalability, ordering and maintenance of the

entire system by any operator. In addition, the Raspberry Pi is preferable as a

central component due to its economical advantages and its large amount of

available documentation and libraries that make it extremely versatile and

usable. This arrangement also responds to the decided premise of using a controller

for each control parameter, thus being able to future expansion both in spatial

redundancy and using sensors and/or actuators of other magnitudes.

2. Agitation Velocity Control.- The

decided first magnitude to control is the system rotation speed with which to

agitate, being of utmost importance in all bioprocesses in order to achieve a

complete mixture of the components and

adequate aeration of the cells of the study compound, mandatory when using

aerobic organisms [3]. Oxygen requirements generally depend on the energy of

the processes steps leading to the product and, because oxygen uptake is linked

to cellular metabolism, oxygen dynamics reflect changes in environmental

conditions. In this respect, the main factors of the design of a bioreactor

that influence agitation are its shape, the number and arrangement of the

blades used, the speed required, the dimensions of the container and the depth

of the poured compound.

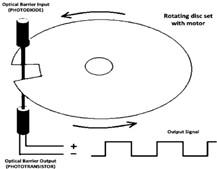

2.1. Agitation

Peripherals.- For the measuring of the speed, it is used a customized system

consisting of rotating a grooved disc attached to the motor shaft represented

in Figure II (a), justified by expensive design alternatives concerning the

adaptation of the encoder. The sensing of the actual agitation speed of the

motor is made by timing each 100µs for native interruptions of the Arduino and

collecting the counter as long as the hole in the slotted disk is not detected.

Once the groove is detected, the calculation is carried out to calculate the

speed at which the disk is fixed to the shaft and therefore the rotation of the

motor. As displayed in Table I, this method achieves in measuring

asynchronously the rotation speed of the blades, getting a heterogeneous error

in the working range. This also involves that the first round of the disk must

necessarily be discarded in order to continue with the magnitudes correct

measurements.

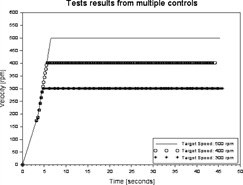

Having

considered several possible actuators such as universal motors and analog

overhead stirrers with DC motors, it remained preferable to use an industrial

induction motor with distinguishing characteristics like availability for high

torque and flexibility in times of use, enabling its continuous operation for

consecutive days. This 6 poles triphasic engine has its speed regulated by the

setup of an attached Variable Frequency Drive (VFD) with multiple internal

registers to configure remotely using Modbus RTU. While testing its performance

it is on one hand observed the precision reached is not entirely acceptable for

accurate usage, keeping a variable error throughout the working range which normally

increments when in lower velocities as presented in Table II. On the other

hand, after an average delay of 1 second as viewed in Figure II (b), the steady

state is reached quickly in critically damped mode, avoiding over-demands to

the system.

|

||||||||||||||||||||||||||||

|

Table I.- Analysis of the relative error in the speed Measurements |

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

|

Table II.- Agitation Subsystem Study: Open Loop Behavior |

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

|

Figure

II.- Survey results of peripherals characteristics |

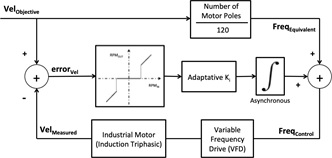

2.2. Velocity Control Description.- Analyzing the

habitual behavior of the rotation speed of the induction motor in front of

different inputs, it is possible to carry out the development of a control

system with the logic shown in Figure III, in order to optimize the response

and precision found in open loop.

|

|

|

Figure III.- Block diagram of proposed

Agitation velocity control |

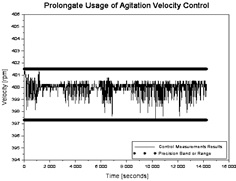

It is therefore proposed to

use an adapted integrative control that allows an integrating parameter

variation depending on the objective values and consequent steps to be made.

This process of adaptation or tuning of the parameters of the integrator is carried

out experimentally and in a multitude of compounds of varied viscosity.

Likewise, a deadband of 1.0 rpm is used with respect to the objective due to

the VFD precision, simultaneously seeking to avoid a permanent oscillation of

the input variable to the system, achieving an acceptable precision and

obtaining the results displayed in Figure IV and Table III.

|

||||||||||||||||||||||||||||||||

|

Table III.- Agitation subsystem study: closed loop observations

|

3. Temperature Control.-

This second magnitude studied is mainly determinant in

the speed or rate of the cell growth process, existing for different

microorganisms and each stage of the fermentation a known optimum temperature

range, found by the scientific community experimentally [4]. In the treated

processes, in case of maintaining the temperature of the organism constant

throughout the fermentation, it would not be necessary to implement any

feedback control, since it would be enough to determine its optimum value.

However, in practice there are multiple internal biochemical reactions which

are system and compound specific and can cause abrupt and arbitrary temperature

changes that are difficult to predict accurately.

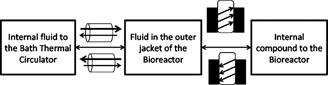

3.1. Thermal Behavior Analysis.- The defined

temperature control subsystem consists of a duly protected RTD Pt100 sensor with OneWire interaction and 0.05◦C precision as well as an external bath

circulator with same internal

sensor type and consequent Fuzzy control of inner fluid. The heat transfer

to the study compound occurs through an outer jacket of stainless steel that is

connected to the circulator by means of aluminum-coated pipes capable of withstanding the 90◦C required

particularly for the system pasteurization

and sterilization. This lays the path to several

bidirectional interactions that affect the system thermal response such as energetic losses by

contact, notorious initial delay response and thermal inertia, as represented

in Figure V.

|

|

|

Figure

V.- Interaction between fundamental components of temperature control |

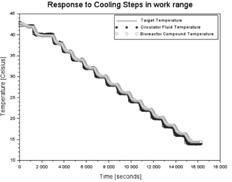

It

is then evaluated the most usual steps in the fermentations worked. These

sections consisted of 18◦C

to 25◦C

intervals (of main relevance

for fungal experiments) and 18◦C to 37◦C

(important range for working with bacteria). These experiences had thus

to be studied carefully by sections and in both

directions (increasing and decreasing the temperature as shown

in Figure VI) in order to observe the greatest number of cases and

behaviors against the same environmental variables.

|

||||||||||||||||||||||||

|

Table IV.- Study by temperature ranges of the compounds steady state |

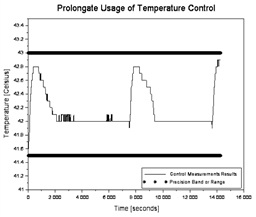

Once analyzed throughout the 5◦C to

95◦C range,

it is observed that the bioreactor

temperature steady state value does

not necessarily reach every time the actuator setting point as displayed in Table IV, arriving at the thermal equilibrium at

the value collected in the container considering the losses and filtrations inherently existing. These

differences are more notorious the

greater the set target, existing sparse discrepancies

at low values. With regard to transient time, no such variation is found in the work range

considered, with an average time of

400 seconds in 2◦C

to 10◦C

steps and with subtle longer duration in initial steps when heating or cooling.

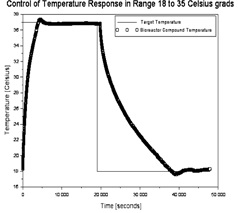

3.2. Temperature

Control Explanation.- At the moment of designing the temperature control

logic, and considering satisfactory the response characteristics observed when

acting the circulator Fuzzy control, it is proposed to perfection its influence

on the general system.

As

shown in Figure VII, the control system design is based on integrators and

derivatives developed in floating control mode in a neighborhood of 3.0◦C and a deadband of 0.2◦C

in order to avoid unnecessary thermal circulator over-use and prevent often visualized permanent

oscillation of the response by temperature.

Outside this interval, the own circulator control

is used in its usual mode. This limitation is found to be

motivated by the desire to evade as much as possible periodic modifications to

the actuator behavior, in order to reduce the probabilities of failures both in

communication and in the equipment

nominal operation. In the same way, the

floating control is simultaneously limited by time as soon as a more frequent and excessive action is

detected when approaching the configured target value. This restraint is

defined in 90 seconds, therefore the conditions must be fulfilled in both time and temperature to allow a

change in the action on the actuator.

This adaptation and selection of parameters achieved

throughout the usual work range work is benefited by the slowness of the observed behavior as

displayed in Figure VIII, which helps dealing with occasional random factors.

|

|

||||

|

Figure VI.- Results example of the system

thermal experiences |

||||

|

|

|||||

|

Figure VII.- Block diagram of proposed temperature

control |

|||||

|

||||

|

Figure VIII.-

Application and testing of proposed temperature control |

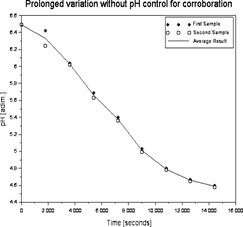

4. Compound pH control.- The

pH in bioprocesses has arbitrary variations both in time and proportion

consequences of predominant chemical reactions that alter the general

conditions of the system, of close relationship with the variations in

temperature of the compound [5]. In order to mitigate abrupt changes in pH and

as a secondary measure, it is common to use buffer components, in order to

maintain the level of acidity or alkalinity

of a substance exposed to chemical reactions, trying to avoid generating

unwanted reactions. This use of conjugates is

what gives these solutions their characteristic resistance to changes

in pH, since it creates

a balance between

acid and base that

is difficult to overcome by other acids or bases. However, when these changes in pH exceed the known capacity of the buffer,

the break occurs, after which the pH will vary radically as if no auxiliary

solution is used.

4.1. Ph Response Examination.- For

the performance of the pH Control it is used two peristaltic pumps controlled

by PWM with corroborated 68µL per drops of acid or base and

an electrode sensor of 0.002 value precision interacted with I2C, capable of

validated with standing temperatures

from 0◦C to

50◦C. So as not to use high resources volumes unnecessarily,

it is proposed a system scaling which delegate equivalent results in consequence of the relative

correlation of substances behaviors to be examined in terms of the buffer solutions concentration and the acids and bases

molarities.

|

||||||||||||||||||

|

Table V.- Experimental

characteristics of differentiated zones |

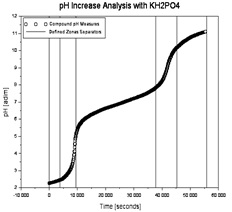

It

is then proceeded to execute sufficient experiments at various intervals in order to have an adequate knowledge of the system characteristics in terms of

their behavior against pH variations, using mainly 1 M solutions

of phosphate buffer (KH2PO4),

sodium acetate (C2H3NaO2),

lacteal medium and proprietary blends with yeasts. According to these experiences,

the existence of several markedly different sensitive areas is appreciated as shown in Figure IX and Table V,

favored by the actuators immediate action on the pH, making it

impossible to collect intermediate values between two contiguous points.

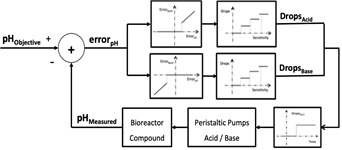

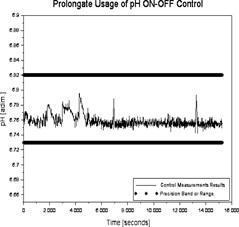

4.2. ON-OFF control Applications.- Based

on the results of previous experiences, an ON-OFF control is proposed, deciding the action according to the current pH error sign and system sensitivity

as represented in Figure X.

Consequently, it is determined the number of drops

necessary to maintain the pH value in a neighborhood of acceptable precision, estimated based on the defined area in which the compound is located at the

measuring moment. It is preferred at

all times the use of the minimum necessary amount of acid and base to prevent

quickly emptying the recipients

carrying the aforementioned performers, while cautioning

avoid oscillations. Then, a 0.05 deadband is used and a minimum time between expulsions of 6 seconds. This leads to

satisfactory results shown in Table VI and Figure XI.

In

order to enable a user customization on the control and provide tools to

increase the flow or speed of the droplet ejection, the actuator is designed to

allow variation of interval and number of drops per burst.

|

||||

|

Figure. IX.- Results of continuous evolution

of pH values in work range |

||||

|

|

||||

|

Figure X.- Block diagram

of proposed pH ON-OFF control |

|

||||||||||||||||||

|

Table VI,- Distinction in zones made by pH control

in ON-OFF mode |

|

||||

|

Figure. XI.- Application and testing of proposed pH

ON-OFF control in lacteal medium with bacteria Streptococcus thermophilus |

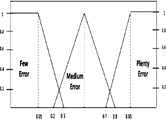

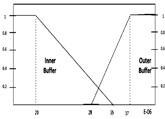

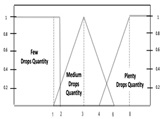

4.3. Fuzzy Control Application.- Alternatively, the

use of Fuzzy control is proposed, which allows

to obtain a definitive conclusion based on vague, ambiguous, imprecise, noisy, inaccessible or unable to mathematically model information, causing

a smooth control output for a wide range of excitations [6]. Thus, three Fuzzy sets are defined: two inputs and one

output, seeking to simplify the design of the control against slight variants

found in the system response. By experimentally defining the three triangular membership functions and if-then

rules shown below, the chosen method for defuzzification is the area centroid.

|

||||||

|

Figure XII.-

Implemented functions of the proposed pH fuzzy control |

(A’∧B2)∨(A0.5∧B’) → C0.5

(A2∧B2)∨(A’∧B’)

→ C’

A2∧B’ →

C2

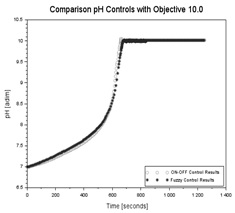

It is then proceeded to compass the same experiments on the buffer solutions, observing a

sufficiently acceptable resulting behavior but with a target arrival time

greater than the previous ON-OFF control, which refers to

have a more satisfactory adaptability

to noted changes. These considerations relate to

the complexities of general optimization of Fuzzy parameters.

5. Remote Management.-

The

security of the data displayed to the user satisfactorily guarantees the

authenticity and integrity of the information,

using symmetric encryption by AES-256 ciphered by blocks according to CBC with padding PKC#7 and hash authorization according to

HMAC-SHA256, ensuring in turn the correct

compatibility between both ends of the remote and

local server [7]. This protection manages to avoid access by any user to restricted data of the

system (such as information from other users, equipment reservations,

fermentation, system status, histories) and that they

can only be viewed, used and edited

through the interfaces provided in the system, by those users who are authenticated and have the authorization for such actions. For this purpose, it is

decided to encrypt and decrypt the

sensitive content once closed and the application started respectively, with backups periodically every hour from the start of the program in case of prolonged use.

The

communication between processes and with the global

program is carried out through shared memory due to its low probability

of access collisions and the impossibility of blockages

due to readings and writings that are not synchronized

between ends. In addition, the slower access of this method of communication is not problematic

as it does not result in extreme

accuracy in the response times and pursuit of data

refreshments on the screen of 10 seconds of interval (for a normal duration

of the 1-week process).

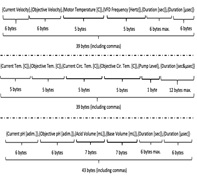

As shown in Figure

XIV, the relevant

information is organized

in system and controls data, with respect to the relevance of the same for the registration and later

visualization of the registered results,

or for the correct functioning of the system.

|

||||

|

Figure XIII.- Comparison between both proposed

alternatives to pH Control |

|

||||||

|

Figure XIV.-

Representation of general system and controls data management |

Both types of data

are therefore treated differently in terms of the protection provided (those

inherent to the overall operation had to be coded and authenticated), being

equally accessible by the instrument operator.

The system sensitive data

makes use of the JSON database format in such a way to simplify its reading by

the remote server and the understanding of the data stored in the local

console, with ease of future expansion. Similarly, the controls general data correspond

to strings of raw numerical values without protection ordered according to a

determined structure that respond to the results obtained from the peripheral

sensors and actuators. This information of the controls allows knowing the characteristics of the current

state of the same and the evolution

of the corresponding parameters of interest of the present fermentation, initializing a new file in each

initialization of the control. For the latter records it is not considered

necessary to use a particular database because of the need for a quick reading

of the information and for the low amount of

data that is normally used.

6. Conclusion.- The proposed

control system successfully achieves in automatically regulate main

bioprocesses parameters like agitation speed, temperature and compound pH. The

former meets a maximum nominal error of approximate 0.8% with superior 0.1%

accuracy, while the temperature reaches an average overdraft of 4.0% and a

maximum steady state error of 2.7%. The latter particular behavior facilitates

the implementation of two possible controls with similar results. Finally, the

globally affordable system design makes place for future possible improvements

and addition of new control parameters.

7. References

[1] M. R. Spier, L. P. de Souza Vandenberghe, A. B. P. Medeiros,

and C. R. Soccol, Application of different

types of bioreactors in bioprocesses. Parana: Univeristy of Parana, Bioprocess

Engineering and Biotechonolgy Department, 2011, pp. 58-69.

[2] J. G.

Akpa, “Modeling of a bioreactor for the fermentation of palmwine by

Saccharomyce cerevisiae (yeast) and lactobacillus (bacteria),” American

Journal of Scientific and Industrial Research, vol. 3, n°4, pp. 231-239,

2012.

[3] Y. Zhou,

L. Han, H. He, B. Sang, D. Yu, J. Feng, and X. Zhang, “Effects of agitation, aeration and temperature on

production of a novel glucoprotein

GP-1 by Streptomyces kanasenisi ZX01 and scale-up based on volumetric oxygen transfer coefficient,” Molecules vol. 23, pp. 1-14, 2018.

[4] R.

Noor, Z. Islam, S. K. Munshi, and F. Rahman,

“Influence of temperature on escherichia coli: growth in different culture media,”

Journal of

Pure and Applied Microbiology, vol. 7, n°2, pp. 899-904, 2013.

[5] P. Sarkar, and G. K. Suraishkumar, “pH

and temperature stresses in bioreactor

cultures: intracellular superoxide levels,”

Industrial & Engineering Chemistry Research, vol. 50, n°23, pp. 13129–13136, 2011.

[6] J. S.

R. Jang, C. T. Sun, and E. Mizutani,

Neuro-fuzzy and soft computing: a computational approach to learning and

machine intelligence. New Jersey: Prentice Hall, 1997, pp. 1-90.

[7] E. S.

I. Harba, “Secure data encryption through a combination of AES, RSA and HMAC,” Engineering, Technology & Applied

Science Research, vol. 17, n°4, pp. 1781-1785,

2017.