Effect of Fiber Angle on Mechanical Properties of the Natural

Fiber-Reinforced Polymer Through Numerical Analysis

Efecto del ángulo de fibra

sobre las propiedades mecánicas del polímero reforzado de fibra natural a

través del análisis numérico

Efeito do ângulo de fibra nas propriedades mecânicas do

polímero reforçado com

fibra natural por meio de análise

numérica

Syed Anas Nisar[1], Tariq Jamil[2]

Recibido: 01/06/2023 Aceptado: 23/07/2023

Summary. - This study focuses on the mechanical behavior

of natural fiber-reinforced polymer composites (NFRPs), which are gaining

prominence as sustainable materials due to their biodegradability and

eco-friendliness. In this study, we aimed to gain a profound understanding of

the mechanical behavior of selected NFRPs. Static structural analysis was

conducted to simulate tensile effects, while vibrational analysis was performed

to predict natural frequencies. The results indicated that all fibers exhibited

minimum stress at the 67.5° angle and maximum stress at the 22.5° angle during

tensile testing. Additionally, minimum deformation occurred at the 0° angle,

whereas maximum deformation was observed at the 67.5° angle. Interestingly, the

NFRPs exhibited similar natural frequencies for the lower modes (1st and 2nd),

with negligible alterations due to fiber angles. The core aim of this study is

to showcase the practicality and viability of the investigated NFRPs by

employing sophisticated finite element analysis to anticipate their material behavior

beforehand, allowing for a comprehensive comparison of the natural frequencies,

stresses, and deformations with traditional Carbon Fiber Reinforced Polymer

(CFRP) composites, thereby exploring the potential of NFRPs as feasible

alternatives.

Keywords: Natural

Fiber; Composite Materials; Numerical Analysis; Structure Analysis; Vibrational

response.

Resumen. - Este estudio se centra en el comportamiento mecánico

de los compuestos de polímeros reforzados con fibra natural (NFRP), que están ganando

prominencia como materiales sostenibles debido a su biodegradabilidad y

eco-amistad. En este estudio, nuestro objetivo fue obtener una comprensión

profunda del comportamiento mecánico de las NFRP seleccionadas. El análisis

estructural estático se realizó para simular los efectos de tracción, mientras

que el análisis vibratorio se realizó para predecir las frecuencias naturales.

Los resultados indicaron que todas las fibras exhibieron estrés mínimo en el

ángulo de 67.5 ° y el estrés máximo en el ángulo de 22.5 ° durante la prueba de

tracción. Además, se produjo una deformación mínima en el ángulo de 0 °,

mientras que se observó una deformación máxima en el ángulo de 67.5 °.

Curiosamente, los NFRP exhibieron frecuencias naturales similares para los modos

inferiores (1 y segundo), con alteraciones insignificantes debido a ángulos de

fibra. El objetivo central de este estudio es mostrar la practicidad y la

viabilidad de los NFRP investigados al emplear un análisis sofisticado de

elementos finitos para anticipar su comportamiento material de antemano, lo que

permite una comparación integral de las frecuencias naturales, tensiones y

deformaciones con el polímero reforzado con fibra de carbono tradicional.

(CFRP) Compuestos, explorando así el potencial de las NFRP como alternativas

factibles.

Palabras clave: Fibra natural; Materiales compuestos; Análisis

numérico; Análisis de estructura; Respuesta vibratoria.

Resumo. -

Este estudo se concentra no comportamento

mecânico dos compósitos

poliméricos reforçados com

fibra natural (NFRPs), que estão

ganhando destaque como materiais

sustentáveis devido à sua biodegradabilidade e eco-filidade. Neste estudo, pretendemos obter uma profunda compreensão do comportamento mecânico dos NFRPs selecionados. A análise estrutural estática foi realizada para simular efeitos

de tração, enquanto a análise vibracional foi realizada

para prever frequências naturais.

Os resultados indicaram que todas

as fibras exibiram tensão

mínima no ângulo de 67,5 ° e tensão

máxima no ângulo de 22,5 ° durante o teste de tração. Além disso,

ocorreu deformação mínima

no ângulo de 0 °, enquanto

a deformação máxima foi

observada no ângulo de 67,5 °. Curiosamente, os NFRPs exibiram frequências naturais semelhantes para os modos inferiores (1º e 2º), com alterações desprezíveis devido a ângulos de fibra. O objetivo central deste

estudo é mostrar a praticidade

e a viabilidade dos NFRPs

investigados, empregando uma

análise de elementos finitos sofisticados para antecipar seu comportamento

material de antemão, permitindo

uma comparação abrangente das frequências naturais, tensões e deformações com polímero de fibra

de carbono tradicional (CFRP) Compostos, explorando assim o potencial dos NFRPs como

alternativas viáveis.

Palavras-chave: Fibra

natural; Materiais compostos;

Análise numérica; Análise

de estrutura; Resposta

vibracional.

1. Introduction. – In

response to the continuous advancements in technology, there is a discernible

global shift towards achieving enhanced durability while simultaneously

reducing the weight-to-strength ratio of materials. In this context, fibers

have emerged as exceptionally robust components, offering notable durability

without compromising the overall weight of the material [1]. Consequently,

composites have emerged as promising alternatives to conventional alloys,

presenting the potential to exhibit comparable mechanical properties while

significantly reducing material consumption [2]. In recent decades, Carbon

Fiber Reinforced Composites (CFRP) have witnessed widespread adoption,

revolutionizing critical mechanical applications across industries such as

aerospace, automotive, and renewable energy. Their exceptional

strength-to-weight ratio and superior mechanical performance have led to their

utilization in vital components ranging from rockets and aircraft to

automobiles and wind turbines [3]. However, with the rapid increase in the

demand for CFRP; the resources in need to produce these composites are also

under question. The availability of minerals is declining rapidly thus

emphasizing the stakeholders to shift to sustainable materials. Natural Fiber

Reinforced Polymer Composite (NFRP) is attracting many scientists and

researchers around the world to develop low-cost, biodegradable recyclable, and

environmentally friendly material. Moreover, they are of lower cost as well.

Thus, in recent decades, scientists have considered NFRP a substitute for

existing CFRP.

The exponential surge in demand for CFRP has

prompted a critical examination of the resources necessary for their

production. The alarming depletion of mineral resources has galvanized

stakeholders to urgently pursue sustainable alternatives. Consequently, NFRP

has emerged as a focal point captivating the attention of scientists and

researchers globally. This interest stems from their potential as highly

cost-effective, biodegradable, recyclable, and environmentally benign materials

[4]– [7]. Notably, NFRPs offer the dual advantage of being ecologically

sustainable and economically viable. Thus, scientific communities have

increasingly considered NFRPs as a compelling substitute for conventional CFRPs

across a wide array of applications. The market share of NFRP has rocketed high

and has already crossed the threshold of $5.83 billion by 2019 [8]. In this

regard, numerous researchers are working around the globe to investigate the

physical properties of NFRP to have a better understanding of the material thus

leading to its application in various potential aspects of engineering. C.M.

Meenakshi and A. Krishnamoorthy conducted a comparative analysis on polyester

composites reinforced with glass, natural, and hybrid fibers. Their findings

indicated that natural fiber-reinforced composites demonstrated favorable

performance characteristics [9]. C. Alves et al. conducted a life cycle

assessment analysis on the replacement of glass fibers with jute fibers as

reinforcement in composite materials for automotive structural components. The

study focused on the environmental performance of the buggy's enclosures as a

case study. The findings revealed that the use of jute fiber composites offered

the most effective solution in enhancing the environmental performance of the

enclosures, thereby contributing to the improved environmental performance of

the entire vehicle [10]. In an extensive

inquiry conducted by Paul Wambua et al., the mechanical properties of

polypropylene composites reinforced with Sisal, Hemp, Coir, Kenaf, and Jute

fibers were meticulously scrutinized. The primary objective was to discern the

impact of varying fiber volume fractions on the composite's performance. The

findings yielded intriguing revelations. Elevated fiber volume fractions

exhibited a pronounced augmentation in both tensile strength and modulus.

Significantly, the investigation evinced that the mechanical properties of the

natural fiber composites exhibited a favorable equivalence to glass mat

polypropylene composites. Intriguingly, in certain instances, the specific

properties of the natural fiber composites even outperformed those of glass

[11].

NFRP is composed of two vital components which are

natural fiber and matrix [12]. Natural fibers are mainly extracted from plants and they could be from plentiful plants thus each

fiber has its own capabilities. Thus, a variety of natural fibers such as

Kenaf, Banana, Jute, Hemp, and PaLF have the

prospectus to provide a stand-in for glass and carbon fibers. Introducing

matrix resin and reinforcing it with fibers considerably rises the properties

of the material. For reinforcing the natural fibers with polymer, it could

either be a thermosetting polymer or thermoplastic. Thermoset polymers are of

significant modulus and of high strength. Thermoset polymers undergo a

crosslinking process during curing, which leads to the formation of

irreversible chemical bonds. Thermoset polymers do possess desirable traits

such as dimensional stability and, in certain cases, cost-effectiveness [13],

[14]. Polyester resins are used widely

for glass fiber-reinforced composites due to low cost, performance properties,

and their easy processing techniques with fillers and reinforcements Polyester

polymer is a viable option that has notable mechanical properties [15]. The mechanical properties of NFRP are based

on various parameters such as angle pf fibers and stacking sequence. Ashwin

Sailesh et al. conducted an experimental investigation on natural fiber

composites reinforced with Kenaf, Aloe Vera, and Jute fibers. The study focused

on exploring the influence of different stacking sequences of the fibers on the

mechanical properties of the composite material. By conducting comprehensive

mechanical testing on the fabricated composites, the researchers determined

that the stacking sequence of the fibers plays a crucial role in determining

the resulting properties of the composite material [16]. Moreover, the

mechanical properties of NFRP are also dependent on the volume fraction and

fiber angle of the fibers. A comprehensive analysis conducted by A. Shalwan and B.F. Yousif explored the mechanical and

tribological characteristics of polymeric composites reinforced with natural

fibers. The study revealed that crucial factors such as surface

characteristics, volume fraction, physical properties, and fiber angle

significantly influence the mechanical and tribological performance of these

composites. Moreover, the researchers established that the inherent nature of

the fibers exerts direct control over the mechanical and tribological behavior

exhibited by the composites [17]. Numerous studies have illuminated the

profound influence of volume fraction and fiber angle on the mechanical

behavior of NFRPs It has been established that these composites exhibit a

remarkable sensitivity to alterations in both volume fraction and fiber angle.

The fiber angle, ranging from 0° to 90°, emerges as a critical parameter that

imparts transformative effects on the material properties. Even the slightest

deviation of a single degree can instigate drastic changes in the resulting

properties of the composites [18]– [22].

Testing all aspects of NFRPs is expensive and

requires bulky funding so examining the properties using modeling and

simulation can be a subtle substitute that can offer a much more accurate

result which might be validated using experimental results in later stages.

There are several tools to perform modeling and simulation of composites

however ANSYS provides various features to feature the actual model, moreover,

it is flexible and can be automated as per requirement. Over its workbench,

finite element analysis and modal analysis can be carried out simultaneously.

Certainly, performed numerical analysis over it is in an acceptable variation

compared with the experimental result. The exhaustive evaluation of NFRPs

entails exorbitant costs, demanding substantial financial allocations. However,

a resourceful alternative lies in the meticulous scrutiny of their properties

through the utilization of modeling and simulation techniques, furnishing a

cost-effective substitute that yields highly precise outcomes. Amidst the

myriad of tools available for composite modeling and simulation, ANSYS emerges

as a preeminent choice, distinguished by its unparalleled versatility and

adeptness in faithfully replicating real-world models. The inherent flexibility

of ANSYS's workbench allows for the concurrent execution of finite element

analysis and modal analysis, affording a comprehensive assessment of the

intricate behavioral dynamics exhibited by NFRPs. Significantly, the numerical

analyses conducted within the ANSYS framework demonstrate an impressive

concurrence with experimental results, thus affirming the unwavering fidelity

and accuracy of the simulation outcomes [23].

Shivanshu Dixit et al. conducted a meticulous finite

element analysis on hybrid composites reinforced with various fibers. ANSYS

Mechanical APDL was employed to prepare a precise 3D model for simulation. Five

distinct combinations of hybrid composites were constructed, incorporating

Banana, Jute, Carbon, Cactus, and Glass fibers, each possessing unique

properties. The models were created

with different angles of the fibers to examine their effects. The specimen models

were dimensioned at 200 x 200 mm with a layer thickness of 0.2 mm. A vertically

compressive force of 200 KN was applied to 17 nodes in the specimens. Several

characteristics, including x-component rotation, y-component rotation,

z-component rotation, x-direction deformation, y-direction deformation,

z-direction deformation, x-component stress, and y-component stress, were

assessed for comparative analysis among the composite materials. Moreover, the

specimens were differentiated based on their angle. Through meticulous

scrutiny, it was determined that the combination of carbon and glass fibers

exhibited the most favorable deformation characteristics, particularly when

arranged in the following sequence: 0°/45°/0°/-45°/0°/90°/0°/45°/0°/-45°. This

specific arrangement showcased the optimum alignment of individual fibers,

resulting in minimal deformation of the composite material [24]. Rakesh Potluri

et al. undertook a comprehensive analysis of the mechanical characteristics of

green composites based on Okra Fiber, employing finite element analysis (FEA)

and theoretical comparisons. Additionally, hybrid laminates combining banana

and kenaf fibers were investigated using FEA. A total of six distinct composite

laminates were meticulously fabricated, featuring varied angles and stacking

sequences. The objective was to thoroughly examine the influence of these

factors on the mechanical properties of the composites. The study established

that an augmentation in the volume fraction of the fiber corresponded to a

significant enhancement in the composite's strength. Remarkably, among all the

laminates investigated, the composite with a stacking sequence of 0°/0°/0°/0°

emerged as the exemplar of strength, exhibiting the highest mechanical prowess.

These compelling findings underscore the pivotal role played by fiber volume

fraction and the optimal stacking sequence in shaping the mechanical behavior

of green composites based on Okra Fiber and hybrid laminates incorporating

banana and kenaf fibers [25]. Siva Bhaskara Rao Devireddy et al. conducted an

extensive study examining the influence of fiber geometry and the

representative volume element (RVE) on the elastic and thermal properties of

unidirectional fiber-reinforced composites. The focus of the investigation was

on glass fiber-reinforced epoxy composites featuring unidirectional fiber

alignment. Using ANSYS software, the researchers constructed an RVE model to

analyze the composite properties. They plotted and analyzed curves illustrating

the relationship between fiber loading and the longitudinal modulus, Poisson's

ratio, transverse modulus, and in-plane shear modulus. Additionally, they

generated curves to investigate the effects of volume fraction on thermal

conductivity. This study provides valuable insights into the effects of fiber

geometry and the representative volume element on the mechanical and thermal

properties of unidirectional fiber-reinforced composites [26].

Vibrational analysis plays a crucial role in

understanding the dynamic behavior and structural performance of composite

materials. By analyzing natural frequencies, mode shapes, and responses to

various vibration types, researchers gain insights into resonance phenomena,

critical frequency ranges, and potential deformations or failures within the

material. This knowledge ensures the safety, reliability, and longevity of

composite structures under real-world conditions. Integrating vibrational

analysis into research methodologies enables a comprehensive understanding of

composite mechanical properties, facilitating optimized design and durability

evaluation for advanced composite-based products. Hamed Akhavan et al.'s study

focused on investigating natural frequencies and mode shapes in variable

stiffness composite laminate plates with curvilinear fibers. By considering

manufacturing constraints, they determined maps of natural frequencies based on

fiber angles. The significance of this research lies in its exploration of

vibrational analysis, which unveils the potential of using curvilinear fibers

to achieve desired vibrational characteristics. By comprehensively

understanding the effects of fiber angles on natural frequencies and mode

shapes, this study offers valuable insights for optimizing the design and

performance of variable stiffness composite laminates in various engineering

applications [27].

Although a great deal of work has already been done

on natural fiber-reinforced polymer composites with circular cross-sections of

fiber, a combination of natural fibers (Kenaf, Banana, Jute, Hemp, and PaLF) with resin polyester is hardly been

reported. To end this, the objective of the present work is to develop a

three-dimensional representative volume element (RVE) with hexagonal packing

geometry with circular fiber cross sections. A numerical homogenization

technique based on finite element analysis was used to evaluate the elastic

modulus and vibrational of the composite. NFRPs are compared with CFRP. The

primary objective of this study is to showcase the practicality and viability

of the investigated NFRPs by employing the powerful tool of finite element

analysis to predict their material behavior beforehand. The intention is to

explore the potential of NFRPs as feasible alternatives to traditional Carbon

Fiber Reinforced Polymer CFRP composites.

2.

Methodology. –

2.1. Material Modeling. – In pursuit of this research endeavor, a discerning process was undertaken

to meticulously select the constituents of the composite materials. The natural

fibers, including Banana, Jute, Hemp, Kenaf, and PaLF,

were meticulously chosen, while the matrix material of resin polyester was

purposefully selected. Before embarking on the finite element analysis of the

NFRPs, it was of paramount importance to ascertain the precise mechanical

properties of both the natural fibers and the resin matrix.

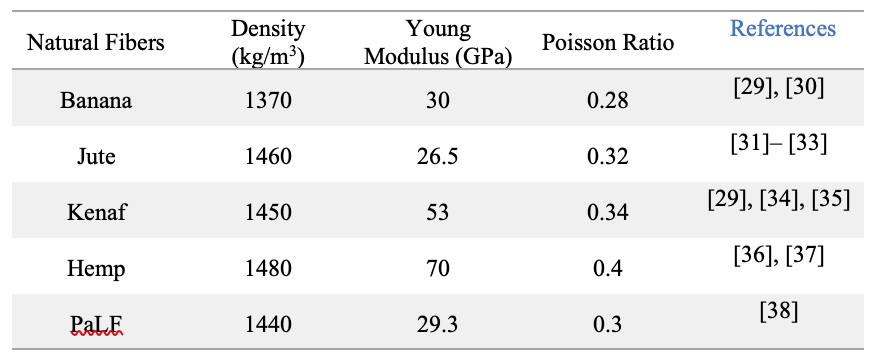

The resin polyester exhibited a formidable elastic

modulus of 3E09 Pascals and an inherent density of 1200 kg/m3 [28]. These

intrinsic properties serve as crucial determinants in delineating the

mechanical behavior of the composite material, exerting a profound influence on

its overall performance and functionality. Table 1, a comprehensive repository

of knowledge, meticulously encapsulates the intricate mechanical properties of

the carefully selected natural fibers, namely Banana, Jute, Hemp, Kenaf, and PaLF. These meticulously documented properties serve as a

gateway to unlocking the inherent characteristics and potential impacts of the

individual fibers on the composite material's performance.

By

meticulously scrutinizing and documenting the precise mechanical properties of

the natural fibers and resin matrix, this research work unearths a profound and

comprehensive understanding of the composite material's behavior and

intricacies. Such profound insights serve as an invaluable reservoir of

knowledge, empowering researchers and engineers to

optimize the design, performance, and durability of Natural Fiber Reinforced

Polymers, thus propelling advancements in diverse engineering applications.

Table I. Mechanical

properties of unidirectional fiber

The present

investigation adopts the Mori-Tanaka (MT) approach as the homogenization

concept for assessing the effective transversely isotropic properties exhibited

by a composite material composed of a two-phase polymer and fiber. By employing

the MT approach, the study aims to evaluate and analyze these properties in a

rigorous scientific manner. In this investigation, a representative volume

element (RVE) was meticulously assembled to maintain a fiber volume fraction

range of 30% within a polymeric matrix as shown in Figure 1. The model assumes

isotropic characteristics for both the natural fibers and polyester, allowing

for an in-depth analysis of the mechanical properties and behavior of the

composite system. This methodological approach ensures a comprehensive and

scientifically sound evaluation of the material's response [39].

|

|

|

Figure I. Representative volume element of

hexagonal array with circular fibers. |

2.2. Numerical

Analysis. – The primary aim of this study was to undertake

an extensive investigation into the mechanical behavior of NFRPs through a

meticulously designed and systematic numerical approach. The fabrication

process of the NFRPs involved the meticulous reinforcement of natural fibers

with a resilient resin matrix, ensuring a consistent and optimal volume

fraction of 30%. The ANSYS Material Designer, a powerful software tool

acclaimed for its robust capabilities in accurately quantifying the stiffness

of diverse unidirectional composite materials, was employed to meticulously

construct the composite [40]. Subsequently, the composite material was exported

and subjected to further processing within the ANSYS ACP, a highly

sophisticated platform meticulously engineered to cater specifically to the

complex demands of composite lamination [41]. The influence of the fiber angle

on the mechanical properties of the composite was accounted for, leading to the

creation of multiple composite configurations, each characterized by distinct

fiber angles, including 0°/0°/0°/0°, +22.5°/-22.5°/+22.5°/-22.5°,

45°/-45°/45°/-45°, +67.5°/-67.5°/+67.5°/-67.5°, and 90°/90°/90°/90°, measured

with precision relative to the horizontal axis. The ensuing simulation phase

entailed the meticulous execution of a series of intricate analyses,

encompassing tensile testing and vibrational analysis.

With

painstaking care, the material properties of the natural fibers and polyester

resin were manually inputted into the ANSYS database, thereby ensuring the most

accurate representation of the composite material. For the purposes of modeling

and analysis, the composite material was assumed to possess isotropic

properties, thereby simplifying the complex calculations and intricate modeling

requirements. Within the ANSYS composite module, the meticulous construction of

a 4-ply laminate ensued, with each ply of the composite possessing a precisely

uniform thickness of 2.5 mm, aligned with the specific fiber angle

configuration. The culmination of these precise and intricate construction

methods yielded the creation of a cantilever beam, characterized by precise

dimensions of 10 x 10 x 100 (height, width, and length), as eloquently

illustrated in Figure 1. The proposed numerical analysis methodology represents

an indispensable and meticulously crafted approach, enabling the comprehensive

exploration of the mechanical behavior of the NFRPs. By ensuring the most

precise representation of the composite material properties and facilitating

Evaluations under diverse loading conditions, this approach empowers

researchers to gain a profound understanding of the composite's intricate

performance characteristics and mechanical responses.

|

|

|

Figure II. CAD model of the cantilever

beam. |

In order to conduct a

comprehensive simulation, the cantilever beam was subjected to a specific

boundary condition. At one end of the beam, a rigid fixation was implemented to

ensure immobilization, while the other end was intentionally left free to

enable unrestricted movement. This configuration enabled the exploration of the

beam's dynamic behavior and response. To analyze the modal characteristics of

the beam, a modal analysis was performed. This involved investigating the

various vibrational modes exhibited by the beam and determining their

corresponding frequencies. By examining these modes and frequencies, a deeper

understanding of the beam's natural oscillations and resonant behavior was

attained.

Furthermore, the tensile

behavior of the cantilever beam was thoroughly investigated. To assess its

response under tensile loading, a precisely controlled force of 100 N was

meticulously applied to the beam. This force was chosen to represent a specific

loading condition of interest. By subjecting the beam to this controlled

tensile force, the structural response and deformation characteristics could be

precisely observed and analyzed. Through the tensile testing, various

parameters such as stress distribution and deformations were determined. This

enabled a comprehensive evaluation of the beam's mechanical properties,

including its ability to withstand applied forces and resist deformation.

Additionally, harmonic response analysis was conducted to explore the beam's

behavior under periodic excitation. By applying harmonic forces at 0 Hz to

10,000 Hz, the dynamic response and resonance characteristics of the beam were

examined. This analysis provided insights into the beam's vibration modes and

natural frequencies.

By undertaking these

simulations and analyses, a comprehensive understanding of the cantilever

beam's structural behavior, dynamic characteristics, and response to loading

conditions was obtained. Such insights are crucial for designing and optimizing

beam structures in various engineering applications.

3. Results and discussions. –

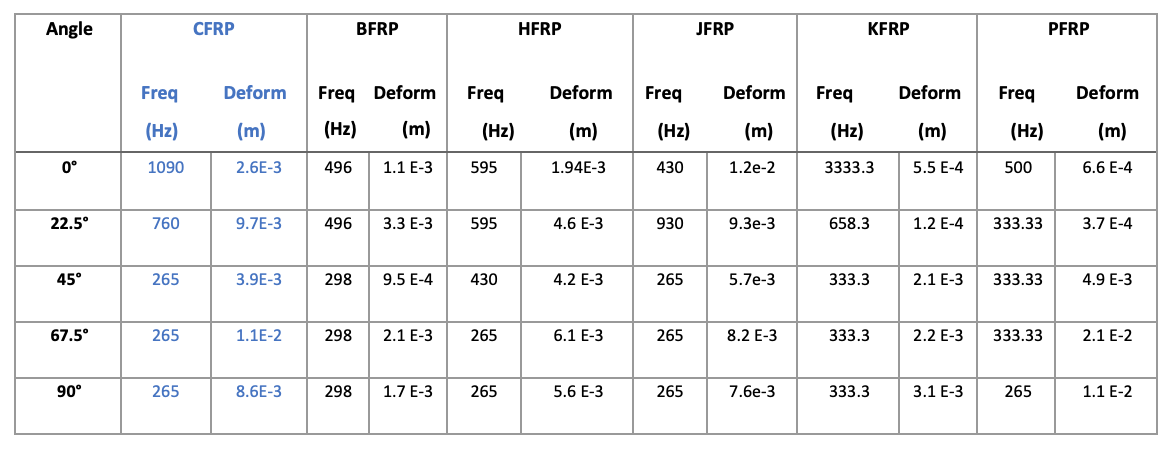

3.1. Vibrational Analysis. – Harmonic analysis of NFRPs was meticulously conducted

using the advanced ANSYS software. A cantilever beam with fixed support was

subjected to a 100 N tensile force, and the harmonic response was analyzed over

a frequency range from 0 Hz to 10,000 Hz. The resulting frequency-amplitude

graph allowed us to record the maximum deformation at each corresponding

frequency, as summarized in Table 2.

Table II. Max amplitude (m) at

corresponding frequencies (Hz) at various angles of NFRPs

The comprehensive examination

of these results unveiled the distinctive frequency responses displayed by each

natural fiber composite. Notably, at fiber angles of 0° and 22.5°, CFRP

exhibited higher levels of deformation compared to NFRPs. However, at 45° fiber

angle, Hemp, Jute, and PaLF demonstrated larger

deformations than CFRP. Furthermore, for fiber angles of 67.5° and 90°, PFRP

displayed higher deformations than CFRP, while the remaining NFRPs exhibited

lower deformations.

In light of these findings, it

is evident that NFRPs showcase varied responses to harmonic loading, making

them suitable candidates for diverse engineering applications. The comparative

analysis against CFRP serves as a crucial benchmark, aiding in the informed selection

of composite materials based on their harmonic behavior. This insight paves the

way for optimizing the design and performance of NFRPs in real-world scenarios,

ensuring their effective utilization as promising alternatives to traditional

CFRP composites.

In pursuit of utilizing

Natural Fiber Reinforced Polymers (NFRPs) as a viable substitute for Carbon

Fiber Reinforced Polymers (CFRP) in various applications, it is imperative to

ascertain the natural frequencies. Neglecting this crucial aspect may lead to

potential damages caused by resonance phenomena within the composite

structures. Therefore, a meticulous analysis of natural frequencies becomes

paramount to ensure the structural integrity and reliable performance of NFRPs

in practical engineering scenarios.

In furtherance of the goal to

use NFRPs as a substitute for CFRP for potential applications, natural

frequencies must have to ascertain else the composite can be damaged due to

resonance. Figure 3 represents the comparison of the first eight mode frequencies

of individual fiber-reinforced composites for several angles .

Banana Fiber Reinforced

Polymer (BFRP); natural frequency comparison is represented in Figure 3a. For

BFRP, it was noted that for the first and second modes, individual fibers are

almost next to each other, and for the first, second, and fifth modes, natural

frequencies are close to each individual composite's angle. While switching

from the fifth to the sixth mode, there is a strong incline seen, and for the

sixth, seventh, and eighth mode shapes, there is a plateau for the respective

angle.

Hemp Fiber Reinforced Polymer

(HFRP); natural frequency comparison is represented in Figure 3b. For HFRP,

individual fibers were seen to be virtually next to one another for the first

and second modes, and natural frequencies were seen to be close to one another

for the first, second, and fifth modes for all possible angles for individual composites. The transition

from the fifth to the sixth mode is accompanied by a strong gradient,

especially for the 0° angle. Moreover, the natural frequency of 67.5° and 90°

are parallel with each other for every mode shape.

Jute Fiber Reinforced Polymer

(JFRP); natural frequency comparison is represented in Figure 3c. For JFRP, it

was witnessed that the fibers are closely located to each other for the 1st and

2nd modes, and the natural frequencies are almost the same for the 1st, 2nd,

and 5th modes, regardless of the composite's angle. A sudden change is

noticeable when moving from the 5th to the 6th mode. Additionally, the natural

frequency of 67.5° and 90° coincide for all modes.

Kemp Fiber Reinforced Polymer

(KFRP); natural frequency comparison is represented in Figure 3d. For KFRP, it

was detected that the fibers are positioned close to each other for both the

1st and 2nd modes, and the natural frequencies are similarly close for the 1st,

2nd, and 5th modes regardless of the composite

angle. A noticeable change in slope was observed when transitioning from

the 5th to the 6th mode. Additionally, the natural frequencies of the 67.5° and

90° angles are consistently in agreement

with each other for all mode shapes.

PaLF Fiber Reinforced

Polymer (PFRP); natural frequency comparison is represented in Figure 3e. For

PFRP, it was perceived that for the 1st and 2nd modes, individual fibers are

nearly neighboring regardless of the fiber angle and for 1st, 2nd, and 5th

modes, natural frequencies are in close proximity of

every angle of individual composites. A sharp tilt can be viewed when

transforming from the 5th to 6th mode. Moreover, the natural frequency of 67.5°

and 90° are consistent with each other for every mode shape.

Figure 3f is for a comparative

analysis of CFRP with polymers enforce with natural fibers.

A comprehensive comparison

will be presented, examining the vibrational characteristics and mechanical

properties of Carbon Fiber Reinforced Polymers (CFRP) in contrast to Natural

Fiber Reinforced Polymers (NFRPs) for each angle.

The angle of fiber 0°:

The examination of natural

fiber composite materials in comparison to CFRP cantilever beam, reveals

intriguing variations in their natural frequencies across different modes for

fiber angle of 0°. For lower modes, Jute, Banana, and PaLF

fibers exhibit lower natural frequencies than CFRP, while Hemp and Kenaf fibers

demonstrate higher frequencies. Conversely, for higher modes, jute, Banana, and

PaLF fibers exhibit lower natural frequencies

compared to CFRP, whereas Hemp and Kenaf fibers present higher frequencies.

This profound exploration underscores the pivotal role of fiber selection and

mode classification in elucidating the dynamic behavior of composite materials

at a fiber angle of 0°.

The angle of the fiber 22.5°:

In this meticulous examination

of natural fiber composite materials (NFRP), comprising Jute, Banana, Hemp,

Kenaf, and PaLF fibers, and their comparison to the

CFRP cantilever beam for a fiber angle of 22.5°, intriguing variations in their

natural frequencies across different modes were unveiled. Notably, in all

modes, the natural fibers exhibited lower natural frequencies than the CFRP

counterpart. Hence, for the specific fiber angle of 22.5°, all NFRPs

demonstrated lower mode frequencies when compared to the CFRP cantilever beam.

This revelation underscores the significance of fiber selection and angle

configuration, paving the way for optimized designs and performance in diverse

engineering applications.

The angle of fiber 45°:

The comprehensive vibrational

analysis of NFRPs at a fiber angle of 45° has revealed intriguing findings.

Notably, for the 1st and 2nd modes, both hemp and PaLF

fibers exhibited higher natural frequencies than the CFRP cantilever beam.

Similarly, for the 3rd and 4th modes, Hemp and Kenaf fibers demonstrated

superior natural frequencies compared to CFRP. Furthermore, in the 5th and 6th

modes, Hemp and Kenaf fibers once again displayed higher natural frequencies

than the CFRP counterpart. Remarkably, in the 7th and 8th modes, Hemp fibers

surpassed the natural frequencies of all other materials, including CFRP. These

remarkable outcomes further emphasize the exceptional vibrational

characteristics of Hemp and Kenaf fibers, underscoring their potential for advanced

engineering applications that demand superior performance and structural

integrity at a fiber angle of 45°.

The angle of fiber 67.5°:

The extensive vibrational

analysis of NFRPs at a fiber angle of 67.5° has led to remarkable discoveries.

All NFRPs, including Hemp, PaLF, Banana, Jute, and

Kenaf, exhibited higher natural frequencies than the CFRP cantilever beam. This

compelling evidence highlights the exceptional vibrational characteristics of

NFRPs and positions them as superior alternatives in terms of vibrational behavior

across various modes. Moreover, for the 5th mode, both Banana, Jute and PaLF fibers demonstrated lower natural frequencies than the

CFRP counterpart. These findings underscore the remarkable performance

capabilities of Hemp and Kenaf fibers in managing vibrational responses and

suggest their potential for engineering applications that demand enhanced

stability and reliable performance at a fiber angle of 67.5°.

The angle of fiber 90°:

The meticulous vibrational

analysis of NFRPs at a fiber angle of 90° has yielded intriguing results.

Remarkably, for the 1st, 2nd, 3rd, 4th, 6th, 7th, and 8th modes, all NFRPs,

exhibited higher natural frequencies than the CFRP cantilever beam. This notable

trend underscores the superior vibrational characteristics of NFRPs in

comparison to CFRP across multiple modes at a fiber angle of 90°. Furthermore,

for the 5th mode, both Hemp and Kenaf fibers demonstrated higher natural

frequencies than the CFRP counterpart. These compelling findings emphasize the

exceptional performance capabilities of Hemp and Kenaf fibers and reaffirm

their potential for advanced engineering applications that necessitate

heightened stability and reliable vibrational response at a fiber angle of 90°.

As the discussion unfolds, a

detailed comparison will be presented, analyzing the distinct vibrational

characteristics and mechanical properties of NFRPs and CFRP across various

angles. This comparative analysis will shed light on the performance disparities

and potential advantages of each material in engineering applications.

|

|

|

Figure III.

Natural frequencies of each composite at 0°/0°/0°/0°,

+22.5°/-22.5°/+22.5°/-22.5°, 45°/-45°/45°/-45°, +67.5°/-67.5°/+67.5°/-67.5°,

and 90°/90°/90°/90° (A) Modal analysis over BFRP (B) Modal analysis over HFRP

(C) Modal analysis over JFRP. (D) Modal analysis over KFRP (E) Modal analysis

over PFRP (F) Modal analysis of CFRP |

3.2. Tensile Test. – In the comprehensive tensile

testing conducted, a meticulous analysis of stress and deformation was

undertaken to discern the intricate mechanical responses exhibited by the

Natural Fiber Reinforced Polymers (NFRPs). The results revealed a remarkable

homogeneity in the response of the NFRPs to the tensile test, shedding light on

their intrinsic mechanical characteristics.

Among

the diverse NFRPs considered in the study, it was observed that those with

fiber angles of 22.5° and 67.5° displayed the most contrasting stress

generation profiles when compared to the samples with different fiber angle

configurations. Notably, these specific angles yielded the worst and best

stress generation, respectively, within the NFRP specimens.

For the

Banana Fiber Reinforced Polymer (BFRP), the von Mises stress generated at a

fiber angle of 22.5° reached 42.2 MPa, while at a fiber angle of 67.5°, it

decreased to 31.8 MPa. The Hemp Fiber Reinforced Polymer (HFRP) exhibited a

stress of 53 MPa at 22.5°, which decreased to 31.8 MPa at 67.5°. In the case of

the Jute Fiber Reinforced Polymer (JFRP), the stress levels observed were 40

MPa at 22.5° and 31.9 MPa at 67.5°. Similarly, the Kenaf Fiber Reinforced

Polymer (KFRP) displayed stress values of 50 MPa at 22.5° and 31.8 MPa at

67.5°. Lastly, the Pineapple Leaf Fiber Reinforced Polymer (PFRP) demonstrated

stress levels of 41.7 MPa at 22.5° and 31.9 MPa at 67.5°. It was concluded that

stresses generated in the NFRPs exponentially increase from 0° with the peak at

22.5° and started gradually decreasing until minimum stress generation at

67.5°.

|

|

|

Figure IV. Comparative Analysis of Tensile

Test-Induced Stress: A Graphical Representation. |

The meticulous observations

presented in this analysis offer illuminating insights into the distinctive

stress generation profiles displayed by the Natural Fiber Reinforced Polymers

(NFRPs) at varying fiber angles, as depicted in Figure 4, in comparison with

the reference material, CFRP. The graphical representation unequivocally

illustrates a striking similarity in stress patterns among all NFRPs and CFRP,

with the maximum stress generation consistently occurring at 22.5° and the

minimum at 67.5°. This unequivocal correspondence between NFRPs and CFRP with

respect to stress distribution at different angles leads to a compelling

conclusion: the stress behavior of NFRPs closely aligns with that of CFRP,

regardless of the angle. Such a finding significantly contributes to our

understanding of the mechanical behavior of NFRPs, bolstering their potential

as a viable substitute for CFRP in various engineering applications.

In the realm of deformations,

meticulous observations revealed intriguing patterns within Natural Fiber

Reinforced Polymers (NFRPs) across different fiber angle configurations.

Notably, the samples with fiber angles of 0° and 67.5° exhibited the most divergent

profiles in terms of deformation generation when compared to the specimens with

alternative fiber angle configurations. These specific angles manifested as the

utmost extremes, representing the most favorable and unfavorable conditions for

deformation generation within the NFRP specimens.

Examining the Banana Fiber

Reinforced Polymer (BFRP), a fiber angle of 0° resulted in a deformation of

1.38 mm, whereas at a fiber angle of 67.5°, the deformation significantly

increased to 3.2 mm. Similarly, the Hemp Fiber Reinforced Polymer (HFRP) displayed

a deformation of 0.68 mm at 0°, escalating to 3 mm at 67.5°. The Jute Fiber

Reinforced Polymer (JFRP) demonstrated deformations of 1.5 mm at 0° and 3.2 mm

at 67.5°. Likewise, the Kenaf Fiber Reinforced Polymer (KFRP) exhibited

deformation values of 0.87 mm at 0° and 3 mm at 67.5°. Lastly, the Pineapple

Leaf Fiber Reinforced Polymer (PFRP) showcased deformations of 1.4 mm at 0° and

3.2 mm at 67.5°. Figure 5 presents a comparative plot of deformations,

depicting the distinct deformation trends across the various fiber angles. The

plot reveals that deformations are minimal at 0°, gradually increasing and

reaching a peak at 67.5°, followed by a slight decline as the fiber angle

approaches 90°.

|

|

|

Figure V.

Comparative Analysis of Deformation Distribution: Visualization of Tensile

Test Results. |

These comparative findings

offer valuable insights into the distinct mechanical behavior of NFRPs,

shedding light on their potential advantages and considerations when compared

to CFRP across various fiber angles. The observed minimal deformation exhibited

by CFRP at angles of 0°, 22.5°, and 45° highlights its superior stiffness in

those configurations. On the other hand, the intriguing results showing lesser

deformation in BFRP and HFRP at angles of 67.5° and 90° emphasize their

potential suitability for applications requiring enhanced flexibility and

resilience. By thoroughly understanding the deformation characteristics of

NFRPs in comparison to CFRP, engineers, and researchers can make informed

decisions regarding material selection for specific engineering applications,

thus advancing the development of robust and optimized composite structures.

4. Conclusion. - In conclusion, our

comprehensive investigation into Natural Fiber Reinforced Polymers (NFRPs) and

their potential as sustainable alternatives to conventional Carbon Fiber

Reinforced Polymers (CFRP) has yielded valuable insights into their mechanical

behavior and performance characteristics. The analysis of vibrational behavior

and tensile testing of NFRPs, along with a comparative examination against

CFRP, has provided a profound understanding of their structural integrity and

suitability for diverse engineering applications.

Regarding

vibrational analysis, NFRPs displayed distinct frequency responses across

different fiber angles. Notably, Hemp and Kenaf fibers exhibited exceptional

performance in managing vibrational responses, making them promising candidates

for applications requiring superior stability and reliable performance. The

comparative analysis against CFRP facilitated the informed selection of

composite materials based on their harmonic behavior, guiding engineers in

optimizing designs for specific engineering requirements.

In the tensile test

analysis, it was evident that stress generation in NFRPs was influenced by the

fiber angle, with the highest stress observed at 22.5° and the lowest at 67.5°.

This trend closely aligned with CFRP, highlighting the potential of NFRPs as

viable substitutes in terms of stress distribution. Additionally, the

deformation patterns of NFRPs exhibited varying trends across fiber angles,

with minimal deformation at 0° and increasing deformations towards 67.5°. This

pattern closely matched that of CFRP. These findings enable engineers to tailor

material selection based on the desired level of flexibility and resilience

required for different engineering applications.

Overall, our investigation underscores the significant

potential of NFRPs as cost-effective, environmentally benign, and mechanically

robust materials for various engineering applications. The meticulous material

modeling using the Mori-Tanaka approach and the numerical analysis methodology

has laid the foundation for a deeper understanding of NFRPs' intricate

mechanical properties and behavior. By leveraging this knowledge, engineers can

design and optimize NFRPs for specific applications, making substantial strides

toward sustainable and resilient engineering solutions in the face of evolving

technological demands. As a result, the global shift towards achieving

sustainability in materials can be accelerated, fostering innovation and

progress in diverse industries, including aerospace, automotive, and renewable

energy.

5. Future Work. - In future work, the

focus should be on further research and development of Natural Fiber Reinforced

Polymers (NFRPs). This includes exploring new natural fibers and matrix

materials, optimizing their properties, and improving the manufacturing

process. Understanding the long-term performance of NFRPs under different

conditions and complex loads is essential for real-world applications. Cost and

environmental impact analyses, along with industry standards, will promote

widespread adoption. Incorporating multifunctional properties in NFRP

composites opens up innovative possibilities for

various engineering sectors, contributing to a more sustainable and

technologically advanced future.

7. References

[1] J. S. Bradley, G. W. Hastings, and C. Johnson-Nurse, ‘Carbon fibre reinforced epoxy as a high strength, low modulus

material for internal fixation plates’, Biomaterials, vol. 1, no. 1,

1980, doi: https://10.1016/0142-9612(80)90057-5.

[2] S. Iqbal, T. Jamil, and S. Murtuza Mehdi,

‘Numerical simulation and validation of MWCNT-CFRP hybrid composite structure

in lightweight satellite design’, Compos Struct, vol. 303, p. 116323,

Jan. 2023, doi: https://10.1016/J.COMPSTRUCT.2022.116323.

[3] M. Saafi, ‘Design and Fabrication of FRP Grids for Aerospace and

Civil Engineering Applications’, J Aerosp Eng,

vol. 13, no. 4, 2000, doi: 10.1061/(asce)0893-1321(2000)13:4(144).

[4] F. M. Al-Oqla and S. M. Sapuan, ‘Natural fiber reinforced polymer composites in

industrial applications: feasibility of date palm fibers for sustainable

automotive industry’, J Clean Prod, vol. 66, pp. 347–354, Mar. 2014, doi: https://10.1016/J.JCLEPRO.2013.10.050.

[5] G. Koronis, A. Silva, and M. Fontul,

‘Green composites: A review of adequate materials for automotive applications’,

Compos B Eng, vol. 44, no. 1, pp. 120–127, Jan. 2013, doi: https://10.1016/J.COMPOSITESB.2012.07.004.

[6] M. P. Ho et al., ‘Critical factors on manufacturing processes

of natural fibre composites’, Compos B Eng,

vol. 43, no. 8, pp. 3549–3562, Dec. 2012, doi: https://10.1016/J.COMPOSITESB.2011.10.001.

[7] Y. Wu, C. Xia, L. Cai, A. C. Garcia, and S. Q. Shi, ‘Development of

natural fiber-reinforced composite with comparable mechanical properties and

reduced energy consumption and environmental impacts for replacing automotive

glass-fiber sheet molding compound’, J Clean Prod, vol. 184, pp. 92–100,

May 2018, doi: https://10.1016/J.JCLEPRO.2018.02.257.

[8] ‘Natural Fiber Composites Market Worth $5.83 Billion by 2019’. https://www.prnewswire.com/news-releases/natural-fiber-composites-market-worth-583-billion-by-2019-285331091.html (accessed Feb. 28, 2023).

[9] M. Idicula, K. Joseph, and S. Thomas, ‘Mechanical performance of

short banana/sisal hybrid fiber reinforced polyester composites’, Journal of

Reinforced Plastics and Composites, vol. 29, no. 1, pp. 12–29, Jan. 2010, doi: https://10.1177/0731684408095033.

[10] C. Alves et al., ‘Ecodesign of

automotive components making use of natural jute fiber composites’, J Clean

Prod, vol. 18, no. 4, pp. 313–327, Mar. 2010, doi:

https://10.1016/J.JCLEPRO.2009.10.022.

[11] P. Wambua, J. Ivens, and I. Verpoest,

‘Natural fibres: Can they replace glass in fibre reinforced plastics?’, Compos Sci Technol,

vol. 63, no. 9, pp. 1259–1264, 2003, doi: https://10.1016/S0266-3538(03)00096-4.

[12] N. Chand and M. Fahim, ‘Tribology of natural fiber polymer composites’.

[13] Y. Li, T. Xie, and G. Yang, ‘Effects of polyphenylene oxide content

on morphology, thermal, and mechanical properties of polyphenylene

oxide/polyamide 6 blends’, J Appl Polym Sci,

vol. 99, no. 5, pp. 2076–2081, Feb. 2006, doi: https://10.1002/app.22687.

[14] R. C. Dante, D. A. Santamaria, and J. M. Gil, ‘Crosslinking and

thermal stability of thermosets based on novolak and

melamine’, J Appl Polym Sci, vol. 114, no. 6,

pp. 4059–4065, Dec. 2009, doi: https://10.1002/app.31114.

[15] G. Gündüz, D. Erol, and N. Akkaş, ‘Mechanical properties of

unsaturated polyester-isocyanate hybrid polymer network and its E-glass

fiber-reinforced composite’, J Compos Mater, vol. 39, no. 17, pp.

1577–1589, 2005, doi: https://10.1177/0021998305051086.

[16] A. Sailesh, R. Arunkumar, and S. Saravanan, ‘Mechanical Properties

and Wear Properties of Kenaf – Aloe Vera – Jute Fiber Reinforced Natural Fiber

Composites’, Mater Today Proc, vol. 5, no. 2, pp. 7184–7190, Jan. 2018, doi: https://10.1016/J.MATPR.2017.11.384.

[17] A. Shalwan and B. F. Yousif, ‘In State of

Art: Mechanical and tribological behaviour of

polymeric composites based on natural fibres’, Mater

Des, vol. 48, pp. 14–24, Jun. 2013, doi:

10.1016/J.MATDES.2012.07.014.

[18] T. Murugan and B. Senthil Kumar, ‘Studies on mechanical and dynamic

mechanical properties of banana fibre nonwoven

composite’, Mater Today Proc, vol. 39, pp. 1254–1258, Jan. 2021, doi: https://10.1016/J.MATPR.2020.04.155.

[19] I. Ben Amor, H. Rekik, H. Kaddami, M. Raihane, M. Arous, and A. Kallel, ‘Effect of Palm Tree

Fiber Orientation on Electrical Properties of Palm Tree Fiber-reinforced

Polyester Composites’, http://dx.doi.org/10.1177/0021998309353961, vol.

44, no. 13, pp. 1553–1568, Dec. 2009, doi: https://10.1177/0021998309353961.

[20] A. Gupta, A. Kumar, A. Patnaik, and S. Biswas, ‘Effect of different

parameters on mechanical and erosion wear behavior of bamboo fiber reinforced

epoxy composites’, Int J Polym Sci, vol. 2011,

2011, doi: https://10.1155/2011/592906.

[21] M. Kumaresan, S. S, and K. .N, ‘Effect of

fiber orientation on mechanical properties of sisal fiber reinforced epoxy

composites’, vol. 18, pp. 289–294, Feb. 2015, doi: https://10.6180/jase.2015.18.3.09.

[22] S. Ben Brahim and R. Ben Cheikh, ‘Influence of fibre

orientation and volume fraction on the tensile properties of unidirectional

Alfa-polyester composite’, Compos Sci Technol, vol. 67, no. 1, pp.

140–147, Jan. 2007, doi: https://10.1016/J.COMPSCITECH.2005.10.006.

[23] B. Noolvi and S. Nagaraj, ‘Modal analysis

of smart composite cantilever beams’, Mater Today Proc, vol. 27, pp.

1720–1722, Jan. 2020, doi: https://10.1016/J.MATPR.2020.03.643.

[24] S. Dixit and S. S. Padhee, ‘Finite

Element Analysis of Fiber Reinforced Hybrid Composites’, 2019. [Online].

Available: www.sciencedirect.comwww.materialstoday.com/proceedings2214-7853

[25] J. K. Paul and S. Abdul kalam, ‘Mechanical Properties

Characterization of Okra Fiber Based Green Composites & Hybrid Laminates’,

2017. [Online]. Available: www.sciencedirect.comwww.materialstoday.com/proceedings

[26] S. B. R. Devireddy and S. Biswas, ‘Effect of Fiber Geometry and

Representative Volume Element on Elastic and Thermal Properties of

Unidirectional Fiber-Reinforced Composites’, J Compos, vol. 2014, pp.

1–12, Nov. 2014, doi: https://10.1155/2014/629175.

[27] H. Akhavan and P. Ribeiro, ‘Natural modes of vibration of variable

stiffness composite laminates with curvilinear fibers’, Compos Struct,

vol. 93, no. 11, pp. 3040–3047, 2011, doi: https://10.1016/j.compstruct.2011.04.027.

[28] M. Ashby, ‘Material property data for engineering materials’, 2021.

[29] P. S. Shankar, K. T. Reddy, V. Chandra, and V. Chandra Sekhar,

‘Mechanical Performance and Analysis of Banana Fiber Reinforced Epoxy

Composites’, 2013.

[30] T. G. Yashas Gowda, M. R. Sanjay, K. Subrahmanya Bhat, P. Madhu, P.

Senthamaraikannan, and B. Yogesha,

‘Polymer matrix-natural fiber composites: An overview’, Cogent Engineering,

vol. 5, no. 1. Cogent OA, Jan. 01, 2018. doi: https://10.1080/23311916.2018.1446667.

[31] M. Y. Khalid, A. Al Rashid, Z. U. Arif, M. F. Sheikh, H. Arshad,

and M. A. Nasir, ‘Tensile strength evaluation of glass/jute fibers reinforced

composites: An experimental and numerical approach’, Results in Engineering,

vol. 10, Jun. 2021, doi: https://10.1016/j.rineng.2021.100232.

[32] A. K. Mohanty, M. Misra, and G. Hinrichsen, ‘Biofibres,

biodegradable polymers and biocomposites: An

overview’, Macromolecular Materials and Engineering, vol. 276–277. pp.

1–24, 2000. doi:

https://10.1002/(SICI)1439-2054(20000301)276:1<1::AID-MAME1>3.0.CO;2-W.

[33] P. Wambua, J. Ivens, and I. Verpoest,

‘Natural fibres: Can they replace glass in fibre reinforced plastics?’, Compos Sci Technol,

vol. 63, no. 9, pp. 1259–1264, 2003, doi: https://10.1016/S0266-3538(03)00096-4.

[34] N. Saba, M. T. Paridah, and M. Jawaid,

‘Mechanical properties of kenaf fibre reinforced

polymer composite: A review’, Construction and Building Materials, vol.

76. Elsevier Ltd, pp. 87–96, Feb. 01, 2015. doi: https://10.1016/j.conbuildmat.2014.11.043.

[35] S. Jeyanthi and J. Janci Rani, ‘Improving Mechanical Properties by

KENAF Natural Long Fiber Reinforced Composite for Automotive Structures’.

[36] M. Rouway et al., ‘Prediction of

Mechanical Performance of Natural Fibers Polypropylene Composites: A Comparison

Study’, in IOP Conference Series: Materials Science and Engineering, IOP

Publishing Ltd, Nov. 2020. doi: https://10.1088/1757-899X/948/1/012031.

[37] R. Bhowmik, S. Das, D. Mallick, and S. S. Gautam, ‘Predicting the

elastic properties of hemp fiber - A comparative study on different polymer

composite’, in Materials Today: Proceedings, Elsevier Ltd, 2021, pp.

2510–2514. doi: https://10.1016/j.matpr.2021.09.562.

[38] R. Potluri, ‘Mechanical Properties of Pineapple Leaf Fiber

Reinforced Epoxy Infused with Silicon Carbide Micro Particles’, Journal of

Natural Fibers, vol. 16, no. 1, pp. 137–151, Jan. 2019, doi:

10.1080/15440478.2017.1410511.

[39] Y. Benveniste, ‘A NEW APPROACH TO THE APPLICATION OF MORI-TANAKA’S

THEORY IN COMPOSITE MATERIALS’, 1987.

[40] S. Bin Rayhan and M. M. Rahman, ‘Modeling elastic properties of

unidirectional composite materials using Ansys Material Designer’, Procedia

Structural Integrity, vol. 28, pp. 1892–1900, Jan. 2020, doi: https://10.1016/J.PROSTR.2020.11.012.

[41] ‘Ansys Mechanical Composite PrepPost

(ACP) Advanced | Ansys Training’. https://www.ansys.com/training-center/course-catalog/structures/ansys-mechanical-composite-prepost-acp-advanced (accessed Mar. 02, 2023).

Nota

contribución de los autores:

1.

Concepción y diseño del estudio

2.

Adquisición de datos

3.

Análisis de datos

4.

Discusión de los resultados

5.

Redacción del manuscrito

6.

Aprobación de la versión final del manuscrito

SAN

ha contribuido en: 1, 2, 3, 4, 5 y 6.

TJ

ha contribuido en: 1, 2, 3, 4, 5 y 6.

Nota

de aceptación: Este artículo fue aprobado por los editores

de la revista Dr. Rafael Sotelo y Mag. Ing. Fernando

A. Hernández Gobertti.